Project Description

Efficient automation with a collaborative robot - Overview

FME Feinmechanik AG relies on two collaborative robots from Universal Robots, the UR5 and the UR10. The aim of the robots is to achieve greater flexibility in production. To this end, the company has now ended shift work. Overall, the company's production processes have become considerably more efficient thanks to automation.

The challenge in the company

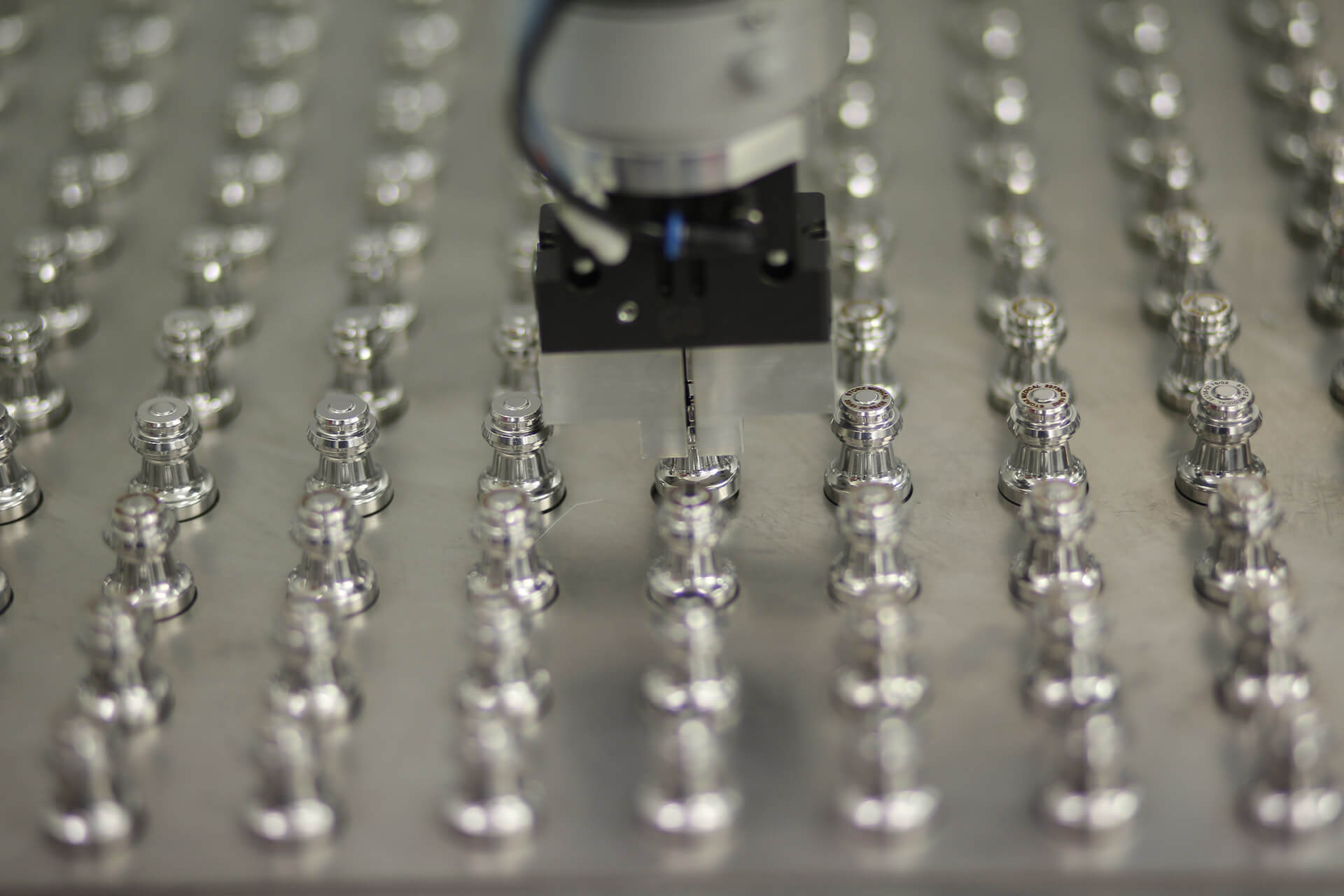

FME Feinmechanik AG is a manufacturer of small, precision mechanical components for medical technology. They are precision-manufactured. Therefore, an automation solution that offers maximum flexibility and produces with the best quality.

The company has not yet considered using industrial robots, as they are considered cumbersome and immobile. This assessment is very important as some production parts are extremely thin-walled, often only half the thickness of a human hair. In addition, the production quantities are between 50-10000 pieces. Complex programming of industrial robots is therefore not profitable.

However, FME Feinmechanik AG had to rethink this assessment. Costs continued to rise, employees with monotonous tasks became more dissatisfied, the demand for products and also the product quantities increased. In view of these prospects, a new solution was needed.

- Maximum flexibility

- Highest precision

Very fine production parts

Cost pressure

High demand

"The robotic arms from Universal Robots have far exceeded my expectations."

The Universal Robots solution

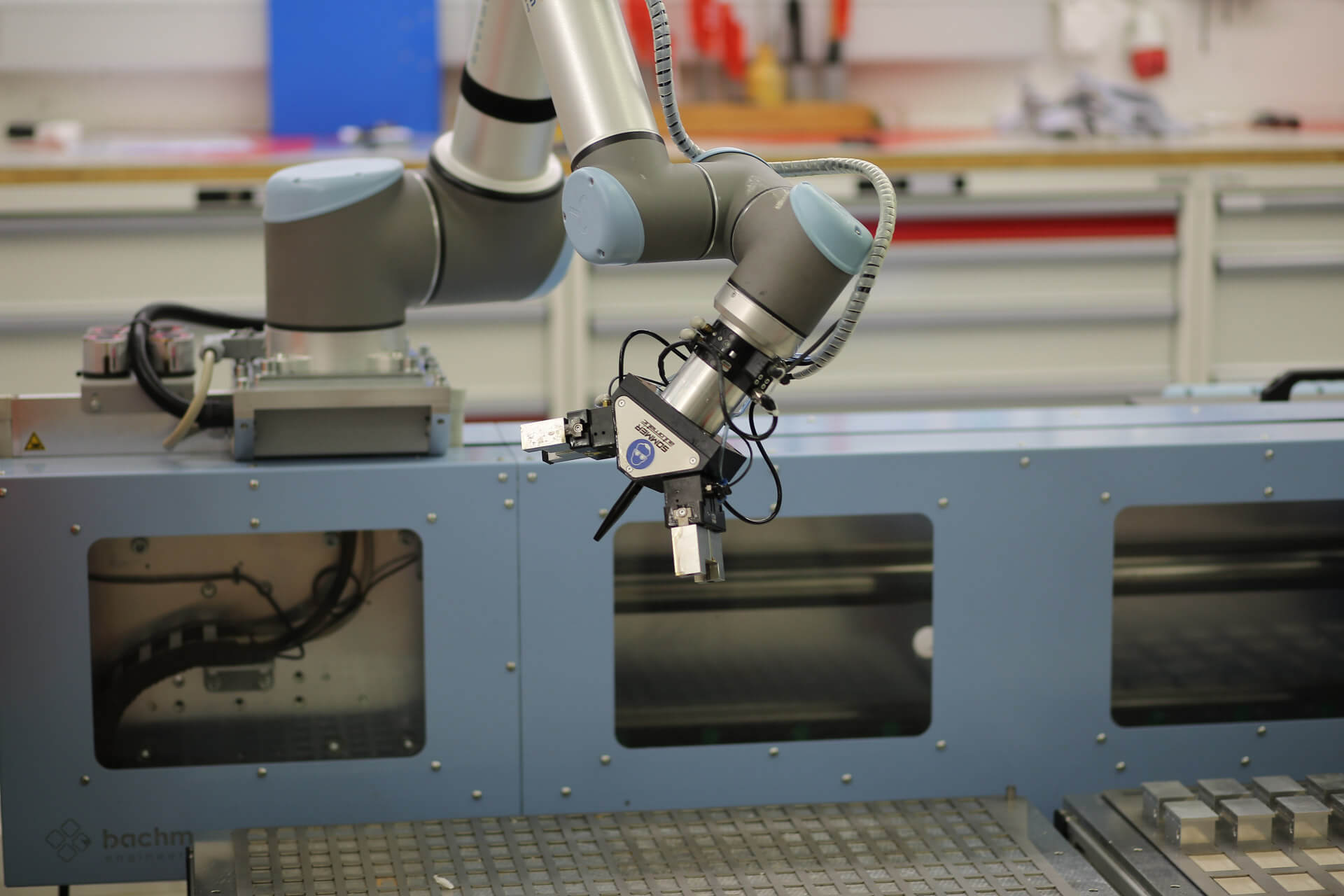

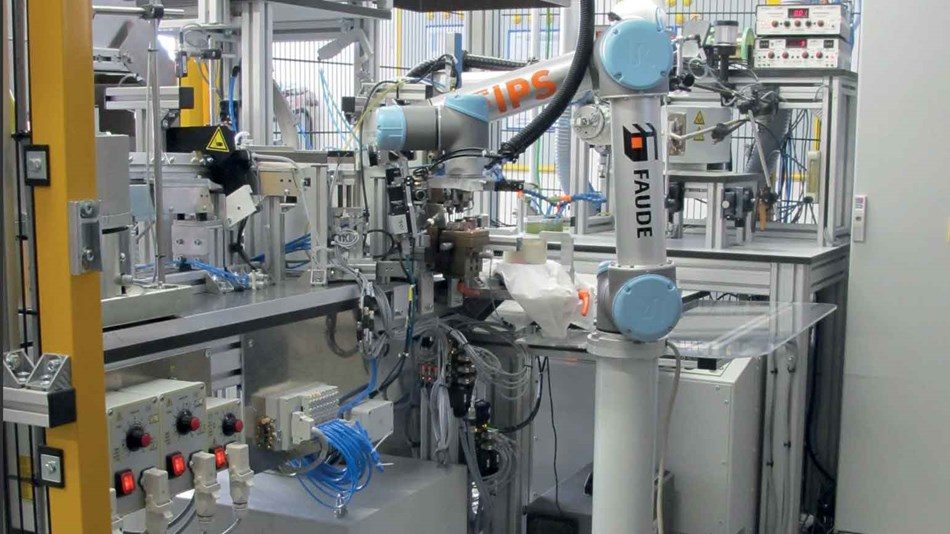

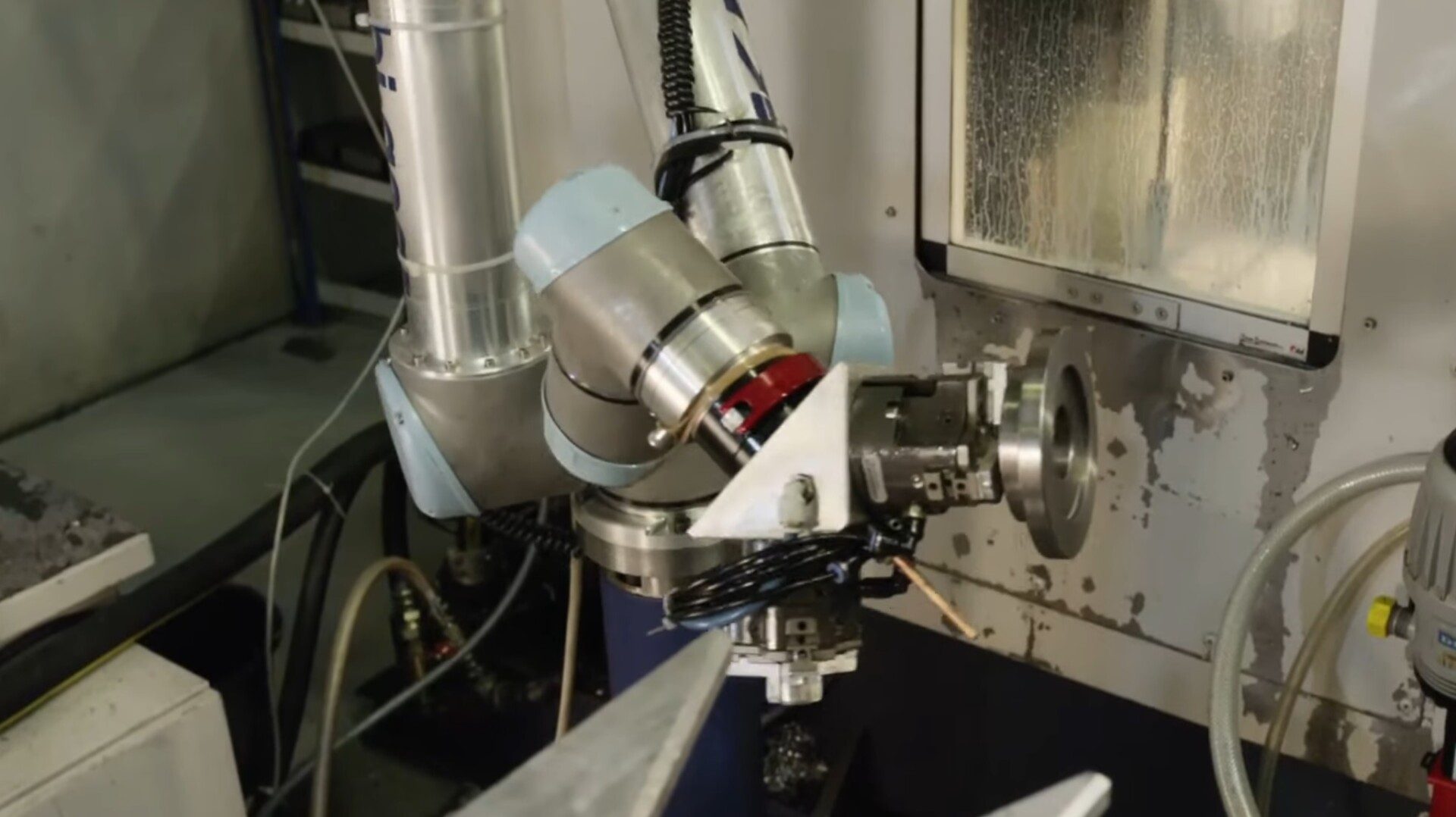

During the consultation, FME Feinmechanik AG was recommended the Universal Robots solution. A stationary and automated system that can guarantee efficient and uninterrupted production of a high standard. In the solution, a UR5 robot can operate two opposing machines, while a UR10 robot is used for feeding. It positions the next component following a signal from the UR5 robot.

The managing director, Marco Bortolan, is very convinced by this solution: "The robot arms from Universal Robots have far exceeded my expectations. The combination of flexibility and ease of programming, as well as the fact that the robots can work directly with my employees without a space-consuming protective housing, were decisive factors that convinced me to invest in this technology and introduce the corresponding changes in our company. Thanks to this success and our positive experience, I can well imagine using more robots in the future."

According to Marco Bortolan, there is usually a preconception that robots threaten jobs. This was not the case at FME Feinmechanik AG. The team even had to be expanded, as productivity could be increased.