Als offizieller Distributor für Universal Robots ist CHROMOS Industrial Dreh- und Angelpunkt für kollaborative Robotik in der Schweiz. Gemeinsam mit unseren zertifizierten Integratoren fördern wir die flexible Automatisierung repetitiver Prozesse.

Bereits heute sind weltweit mehr als 60.000 Roboter von Universal Robots im Einsatz. Überzeugen Sie sich selbst von den vielfältigen Einsatzmöglichkeiten für die Automatisierung in Ihrem Unternehmen.

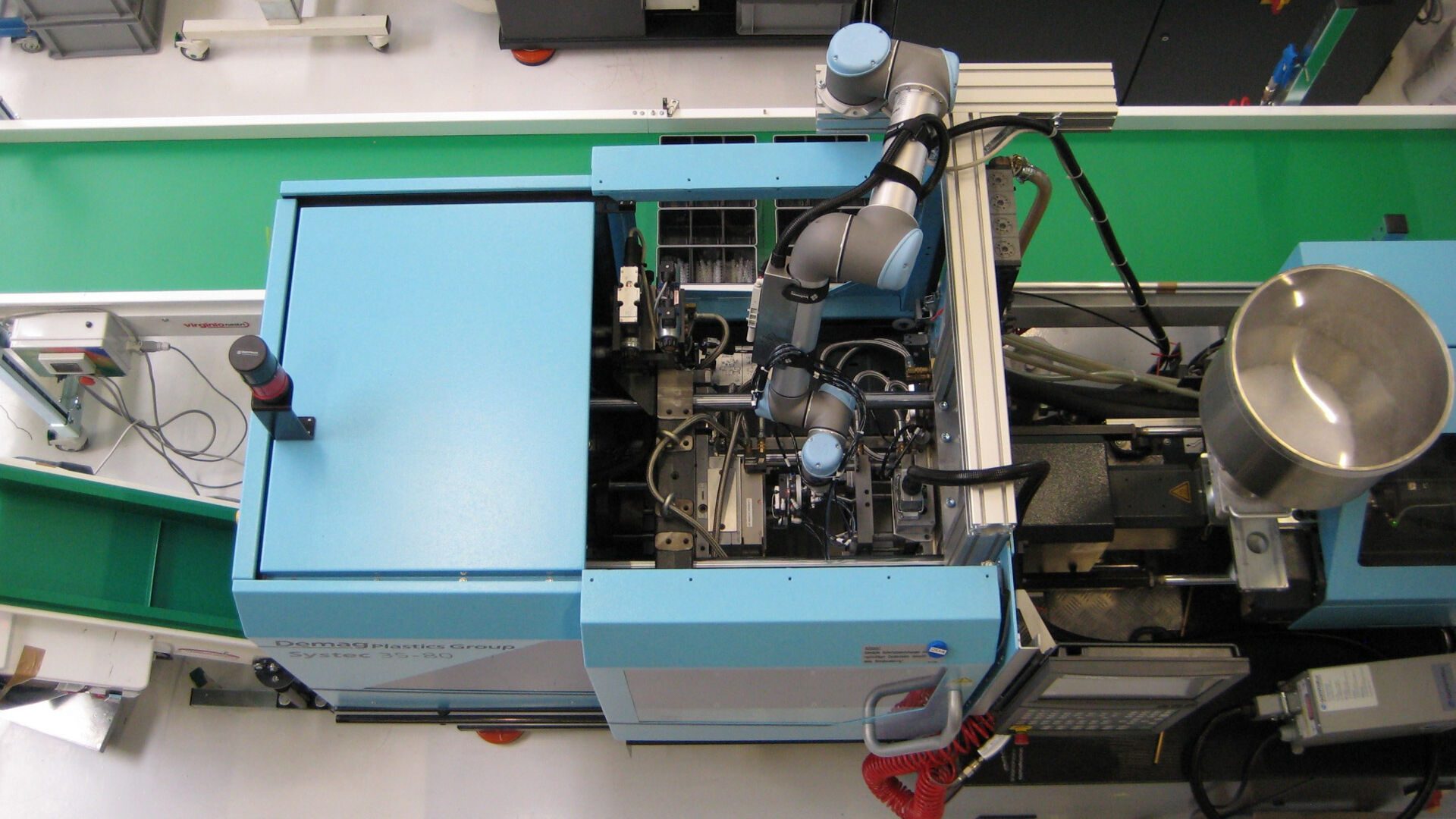

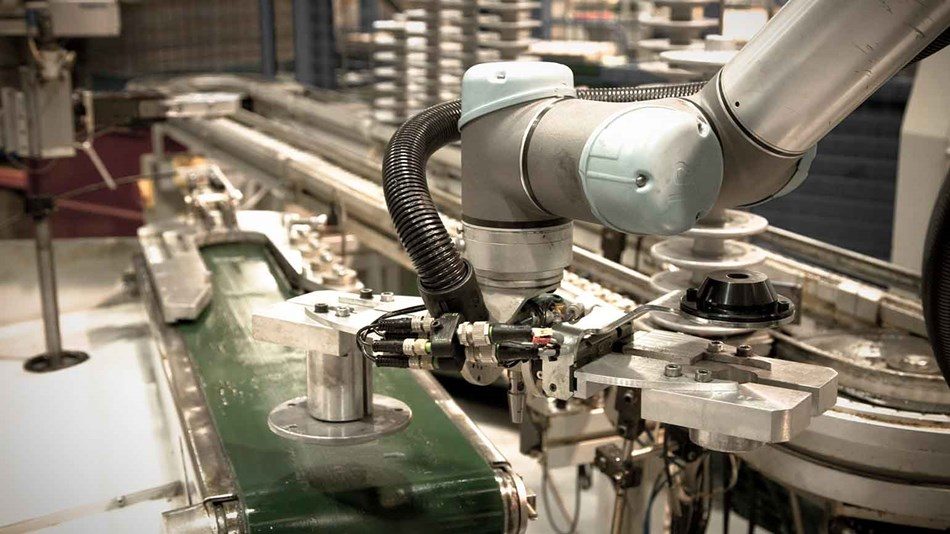

Cobots von UR im Einsatz

Besuchen Sie die nächsten Cobot Events

Core Training – Zertifizierte UR Academy Cobot Schulung

Core Training – Zertifizierte UR Academy Cobot Schulung

Core Training – Zertifizierte UR Academy Cobot Schulung

Core Training – Zertifizierte UR Academy Cobot Schulung

Bringen Sie die Automatisierung voran

Warum sind Cobots so wichtig?

Schweizer Unternehmen, unabhängig von ihrer Grösse, stehen vor erheblichem Druck. Die Konkurrenz holt kontinuierlich auf, qualifizierte Fachkräfte werden knapper, die Kosten steigen unaufhörlich und die Anforderungen an neue Mitarbeiter entwickeln sich ständig weiter.

In diesem Zusammenhang bietet ein kosteneffizienter, flexibler und zuverlässiger Robotereinsatz eine äusserst erfolgversprechende Lösung. Diese automatisierten Systeme übernehmen monotone und unbeliebte Aufgaben von Mitarbeitern, steigern die Produktivität und tragen somit massgeblich zur Verbesserung der Wettbewerbsfähigkeit bei.

Unser besonderes Augenmerk liegt darauf, kleinen und mittelständischen Unternehmen in der Schweiz zu helfen, ihre Wettbewerbsfähigkeit zu stärken und den Produktionsstandort Schweiz zu erhalten.

Flexibel und kostensparend

Welche Vorteile bieten die Cobots von Universal Robots?

Ist der Mangel an qualifizierten Fachkräften eine Bremse für Ihren Unternehmenserfolg? Nutzen Sie das Potenzial Ihrer Mitarbeiter für anspruchsvollere Aufgaben, während kollaborative Roboter gerne die sich wiederholenden Aufgaben erledigen.

Cobots sind bereits in vielen Unternehmen im Einsatz und bieten auch Ihrem Unternehmen die Möglichkeit zur Steigerung der Effizienz.

Lernen Sie alles über Cobots

Bevor Sie die Entscheidung zum Kauf eines kollaborierenden Roboters treffen, möchten Sie vielleicht mehr Informationen über diese Technologie erhalten. In diesem Fall empfehlen wir Ihnen, einen Blick auf unsere kostenlosen Ressourcen, die UR+ Lösungen oder die Universal Robots Academy zu werfen.

FEATURED

Was kostet ein Cobot?

Wie hoch ist der Cobot Preis? Diese Frage lässt sich nicht allgemein mit einer Zahl beantworten. Deshalb schauen wir uns die einzelnen Kostenblöcke beim Einsatz eines kollaborierenden Roboters an und gehen der Frage nach, ab wann sich eine Investition für Sie als Anwender lohnt.