Ensure consistently high product quality with collaborative robots

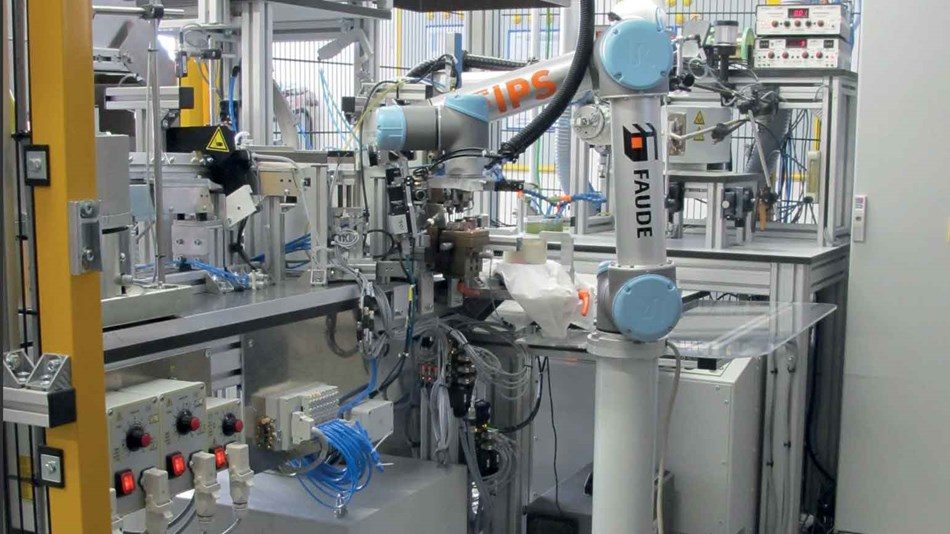

Cobots, also known as collaborative robots, are revolutionizing quality inspection in the industry. Universal Robots (UR) offers flexible and user-friendly solutions specifically designed to work together with humans. These robotic arms are easily programmable and can be quickly integrated into existing production lines.

In quality inspection, UR cobots offer numerous advantages: they increase the precision and consistency of inspection processes, reduce human error and improve workplace safety by relieving workers of repetitive and tiring tasks. The cobots are also space-saving and can be easily repositioned, making them ideal for various quality inspection applications in small and medium-sized businesses.

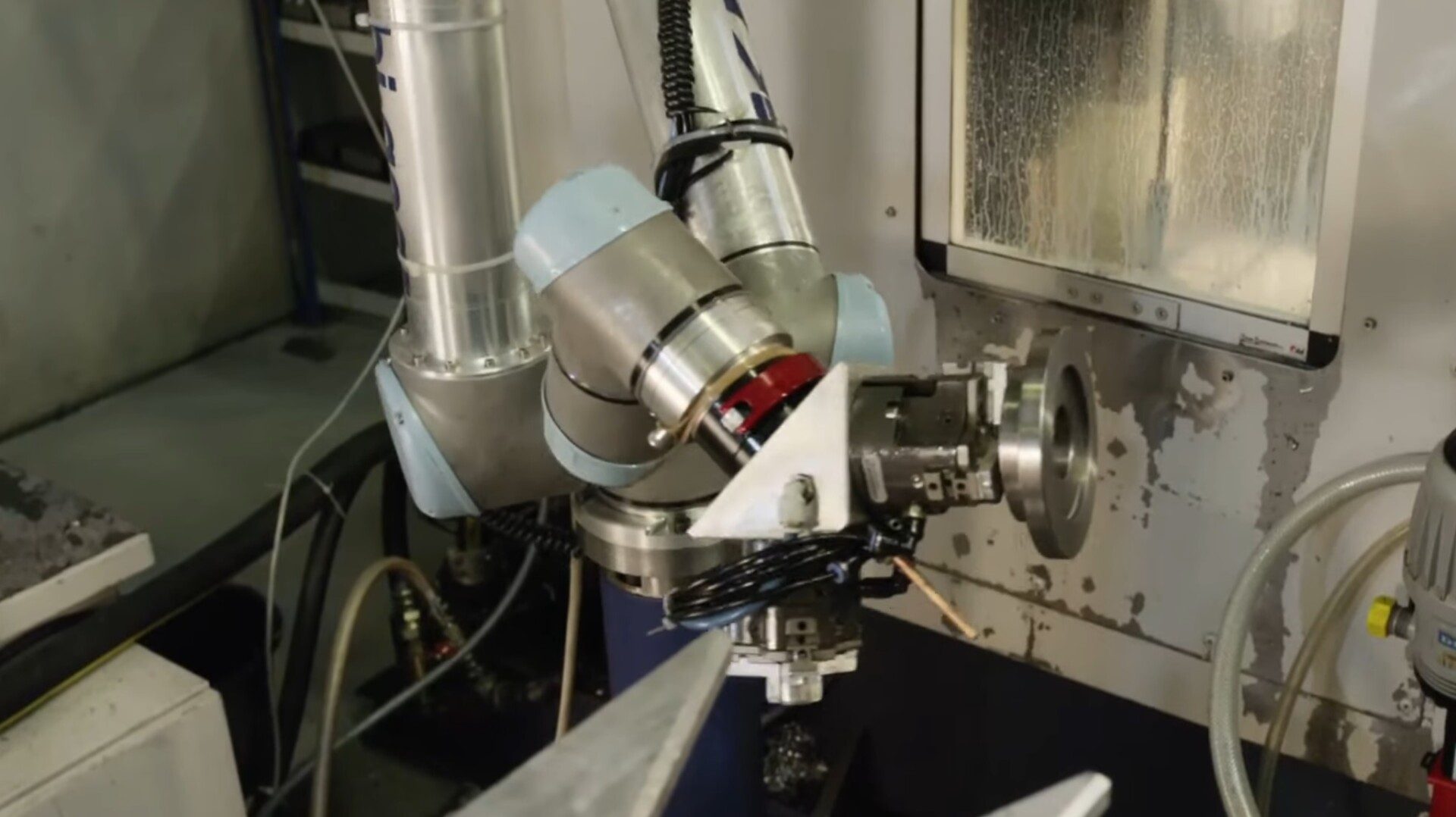

A particularly convincing argument for using the UR cobots is their high repeat accuracy of +/- 0.03 mm (30 micrometers). This precision ensures that every inspection is carried out accurately and reliably, which ensures consistently high product quality.

The flexibility of the UR cobots makes it possible to carry out different inspection procedures, including optical inspection, metrology, non-destructive testing and surface analysis. With integrated sensors and the ability to communicate seamlessly with other machines, they ensure efficient and high-quality production. Companies benefit from reduced costs, increased productivity and greater competitiveness on the market.

Challenges in the application

What can this look like in reality?

Case studies

Learn all about cobots

Before you make the decision to purchase a collaborative robot, you may want to find out more information about this technology. In this case, we recommend that you take a look at our free resources, the UR+ solutions or the Universal Robots Academy.