Project Description

Result at a glance

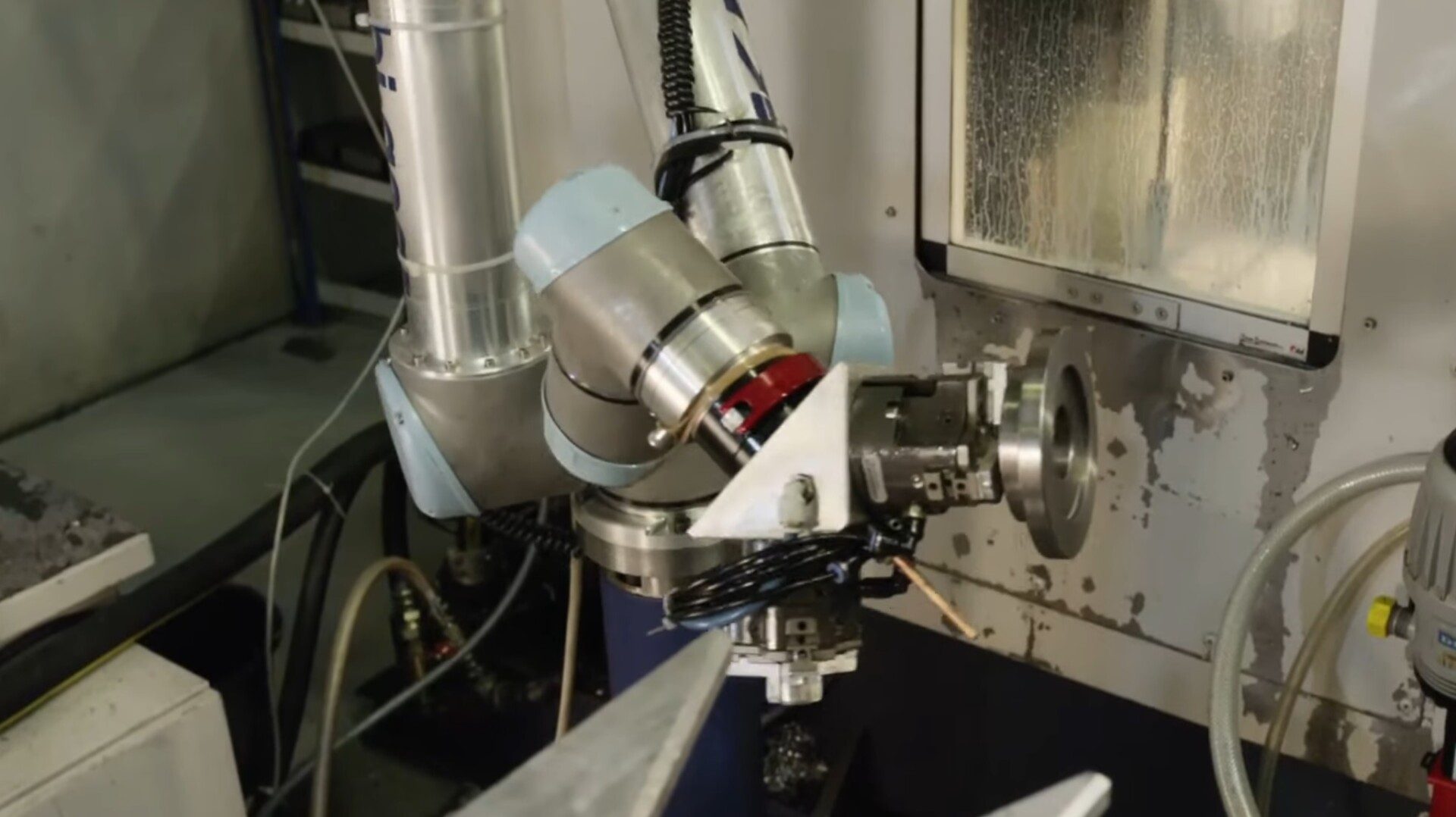

Paradigm, a manufacturer of high-performance loudspeakers, relies on cobots from Universal Robots. In order to meet the demand for labor-intensive products, the polishing area had to be automated with cobots. This significantly increased production output and also greatly improved the working environment.

"Thanks to the robots from Universal Robots, we were able to increase our throughput by 50%."

The challenge in the company

The "Midnight Cherry" finish was launched by Paradigm for a new range of speakers. Demand was significantly higher than expected. So significantly more speakers had to be produced.

"To achieve this finish, you have to apply several coats of paint, and after applying each coat you have to polish, polish, polish. This involves a lot of manual work. The difficulty here is to find skilled workers for this task; we simply could not find enough qualified workers," explained Oleg Bogdanov, Technical Director.

There was even a Cartesian robot in operation. However, this required a high level of safety precautions to ensure that employees were not put at risk.

According to John Phillips, Senior Manager of Production Services, there was previously no way for a robot to work together with an employee. However, this was necessary as the machine had to be closely monitored during polishing. However, it is precisely this control that is not possible with a separate robot cell.

New challenging product

High demand

Security fencing not possible

The Universal Robots solution

Through an expert, Paradigm became aware of the collaborative robots from Universal Robots and that they could be a solution to the problem in the "Midnight Cherry" area.

"Collaborative robots were a new technology and we did a lot of research into them. This type of robot makes it possible for a human and a robot to work together in the same workspace. Robots and humans now work in pendulum operations, where interaction is possible in a safe environment and the human can check that the robot has done the job properly before the final polishing is carried out by the human. These workflows are based on very close collaboration," explains Phillips.

For conventional robots, many safety precautions have to be taken to ensure that employees have a safe working environment. This makes the introduction period very long. The introduction of the Cartesian robot at Paradigm took 5 months. In comparison, the introduction of Universal Robots' cobot took only one month.

Another advantage of the cobots is the built-in force feedback function. The pressure that the robot arm should exert can be set precisely in the user interface of the collaborative robots from Universal Robots. This is particularly important when polishing sensitive surfaces.

Paradigm is already working on other applications that can be automated with a UR robot.

UR5 robot at Paradigm