Project Description

The result - pick & place application for highly sensitive glass tubes

To enable Hofmann Glastechnik GmbH to make better use of its employees' potential and optimize production processes, the company relies on automation with cobots. Two collaborative robots from Universal Robots have been used to automate repetitive and manual tasks in particular. They now take over the automatic machine loading for the series production of highly sensitive glass cuvettes.

This improves the quality of the products, reduces the workload on employees and stabilizes production processes.

The challenge in the company

Handling highly sensitive glass tubes requires maximum precision and delicacy. For this reason, machine loading was previously carried out by employees. However, these highly qualified employees can be deployed much more effectively.

For this reason, the company was looking for robots that could perform these highly sensitive tasks. With the collaborative robots from Universal Robots, the company found the right ones.

"The glass is extremely sensitive. Even the smallest temperature changes on the tools have an effect on the forming result. Our employees used to load the glass lathes manually. Even short interruptions in the work process naturally caused the machines to cool down again and again. When we used the collaborative UR robots for this task for the first time, we suddenly got top results," explains Robert Hofmann, Managing Director at Hofmann Glastechnik.

Another challenge in the company is the necessary flexibility. The cobots must be able to be quickly assigned to other tasks.

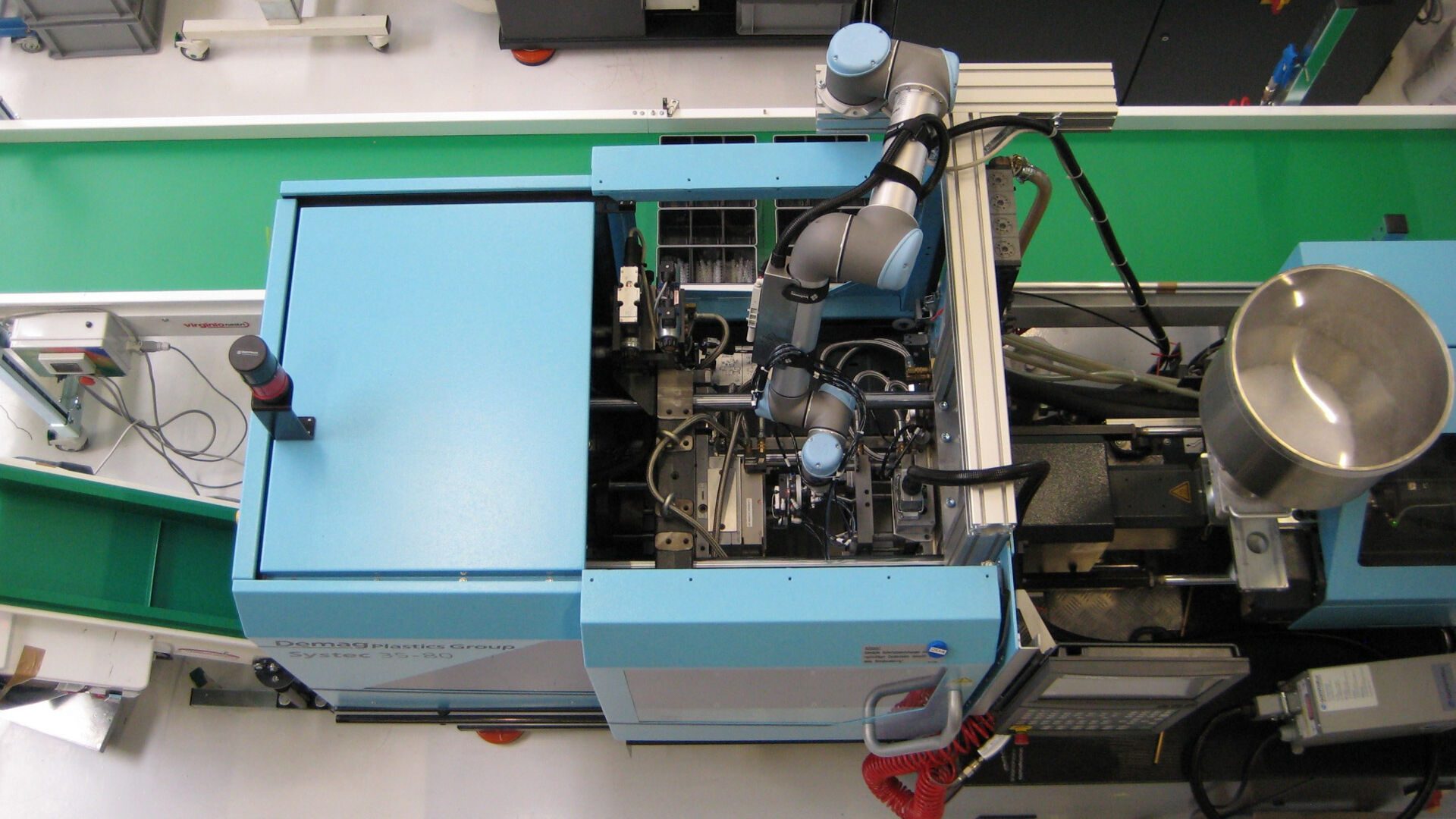

In their regular work, a UR5 and a UR10 robot feed the production components to several PLC-controlled glass lathes. They do this for up to eleven hours a day.

The company has developed a mobile device so that they can also be used flexibly at other workstations. With this device, the robots can easily be assigned to other workstations and immediately continue with this task.

The Universal Robots solution

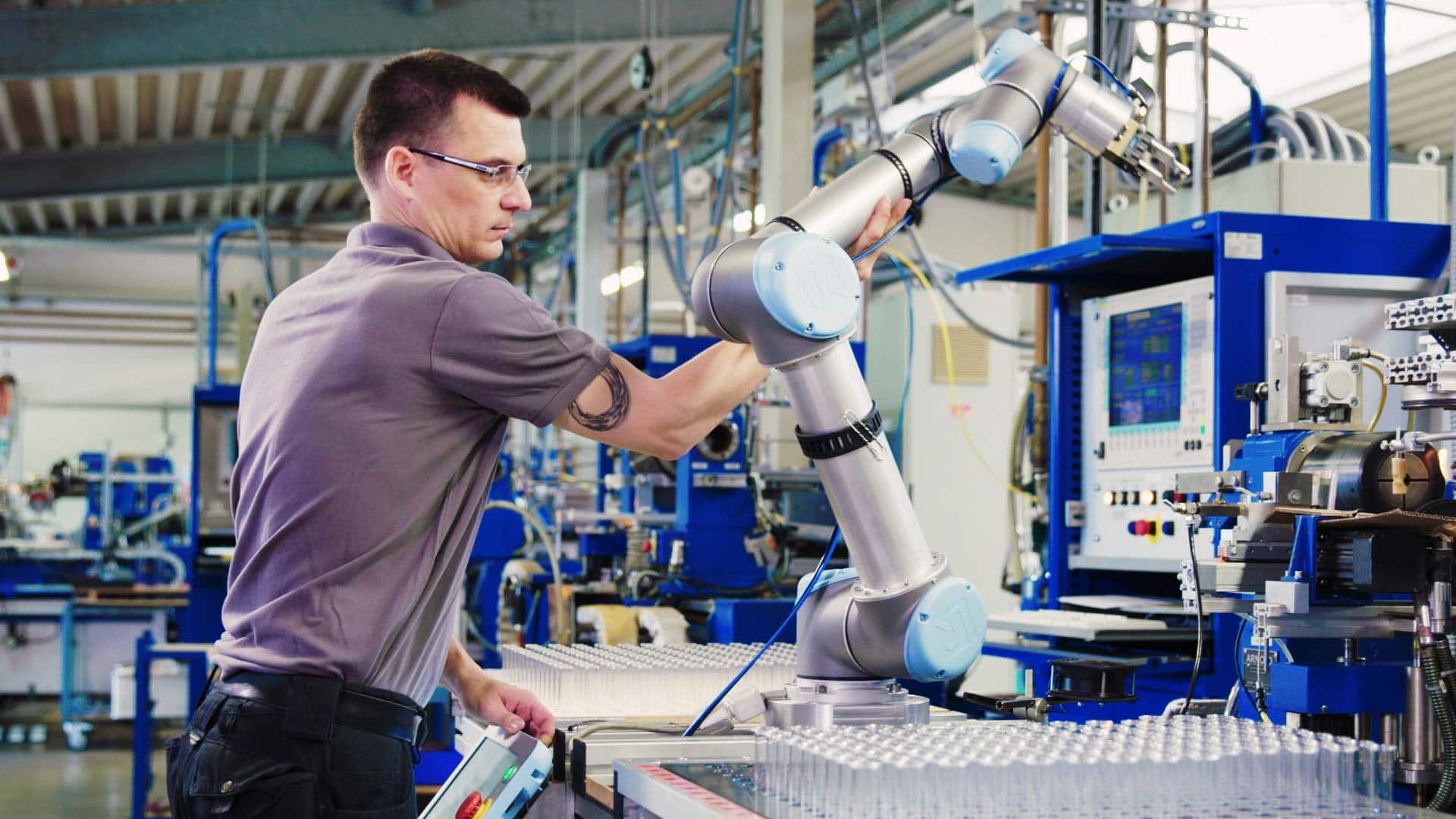

Björn Uthe, head of the machinery department at Hofmann, was immediately impressed by the user-friendliness of the cobots.

"The handling of the UR robots is really very intuitive. Once you understand the processes and functions behind them, the robots can be operated by anyone. In the past, we always had to walk back and forth between the individual glass lathes and load them in parallel. In principle, we could hardly keep up with production. Since the UR5 and UR10 have been working for us, I can spend more time setting up the machines again"

The collaborative robots from Universal Robots enable Hofmann Glastechnik GmbH to achieve various goals. Employees are deployed for more demanding tasks, downtimes are reduced and production processes are stabilized.

Overall, the company has achieved a significant improvement in quality and increased efficiency. In addition, production capacities were increased by 50%. The investment in collaborative robots paid for itself after just 6 months.

Cobots at Hofmann Glastechnik