Project Description

How do you produce profitably in Switzerland? - The result

Profatec AG was faced with the decision of whether to outsource production to the Asian market. This decision was necessary as production was to be expanded. However, thanks to the installation of various robot arms, this was not necessary. Production can continue to be carried out in Switzerland.

The challenge in the company

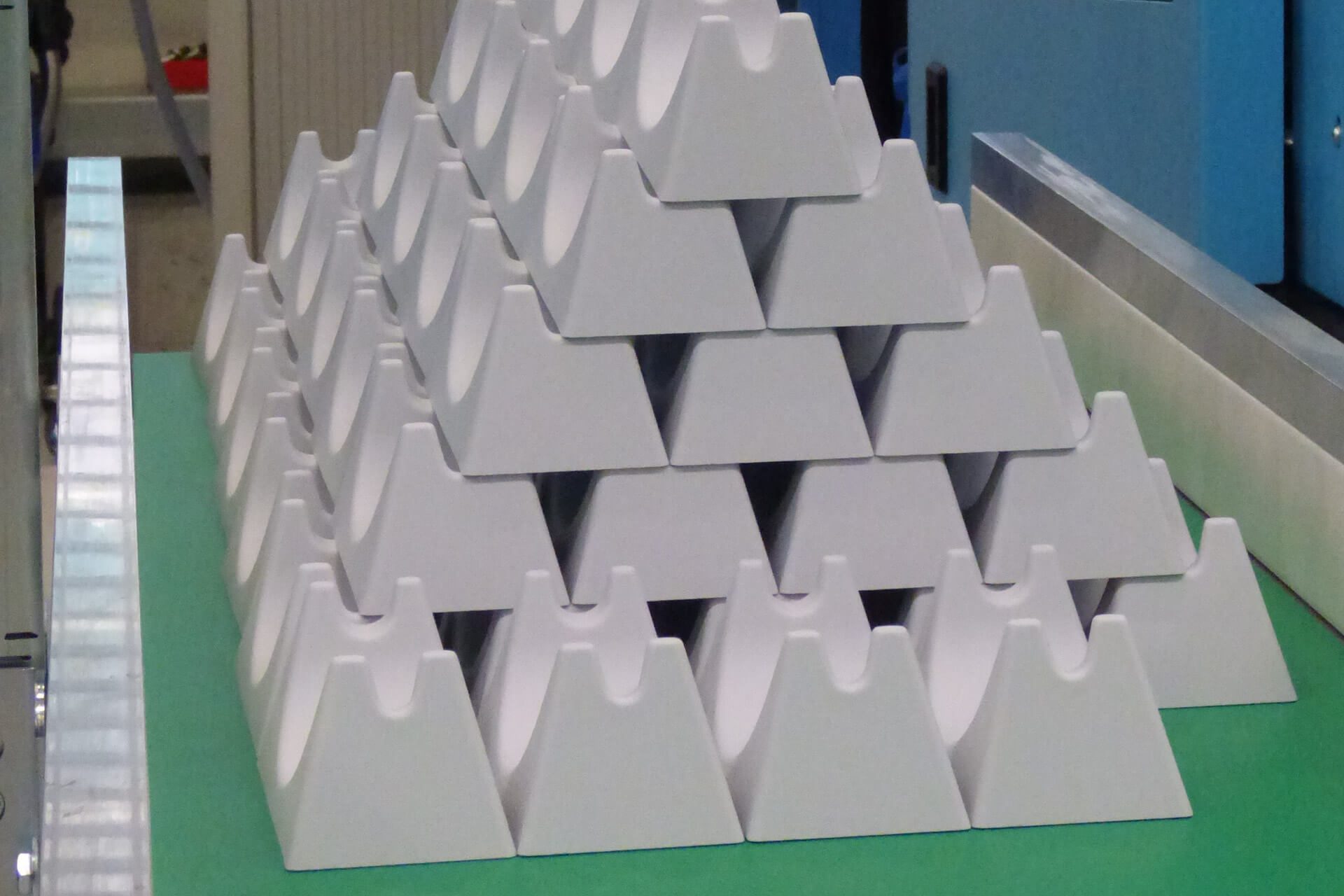

Profatec AG was founded in Malans in 2003. For more than a decade now, the company has been offering specially molded plastic solutions for various industries, such as the automotive and pharmaceutical sectors.

Injection molding was then to be added to the product range in 2007 for further company growth. This was intended to achieve higher profitability and other goals.

In this case, small companies usually have to fall back on manufacturers in the Asian market. Companies like Profatec cannot always quickly provide more space and hire additional employees. To ensure that production can still grow in Switzerland, the company turned to Universal Robots with the question of automating production.

Competitive pressure

Cost pressure

Expansion necessary

"Without our robots, we wouldn't stand a chance against the lower prices from China. We are therefore all the more satisfied that we have succeeded and that we are able to go in the other direction to secure jobs in Malans and free our employees from monotonous tasks."

The Universal Robots solution

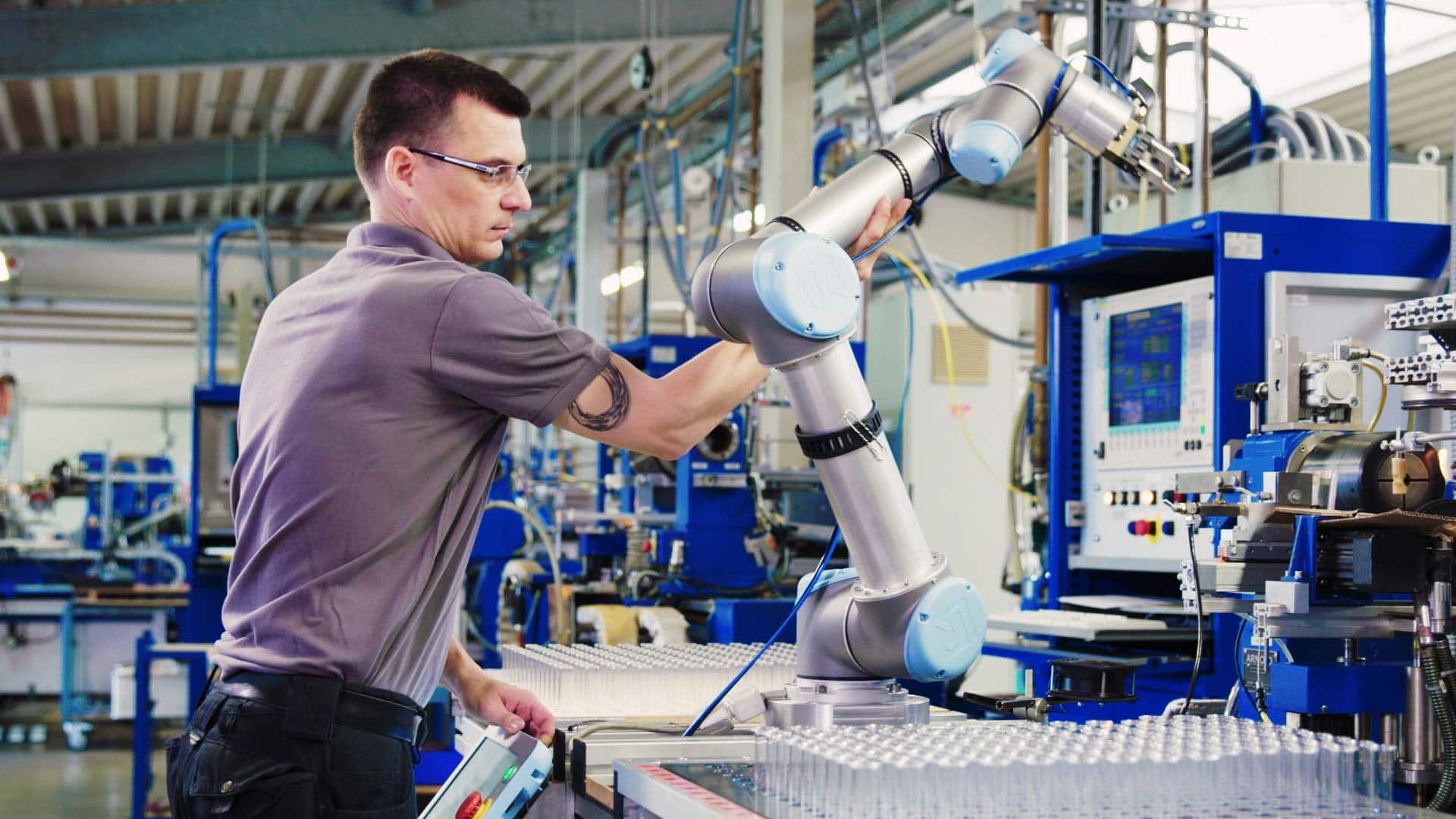

Two things were particularly important for Profatec. The machines must be quickly adaptable to the injection of new plastic parts and the processes must be fast and flexible so that smaller order quantities can also be handled well.

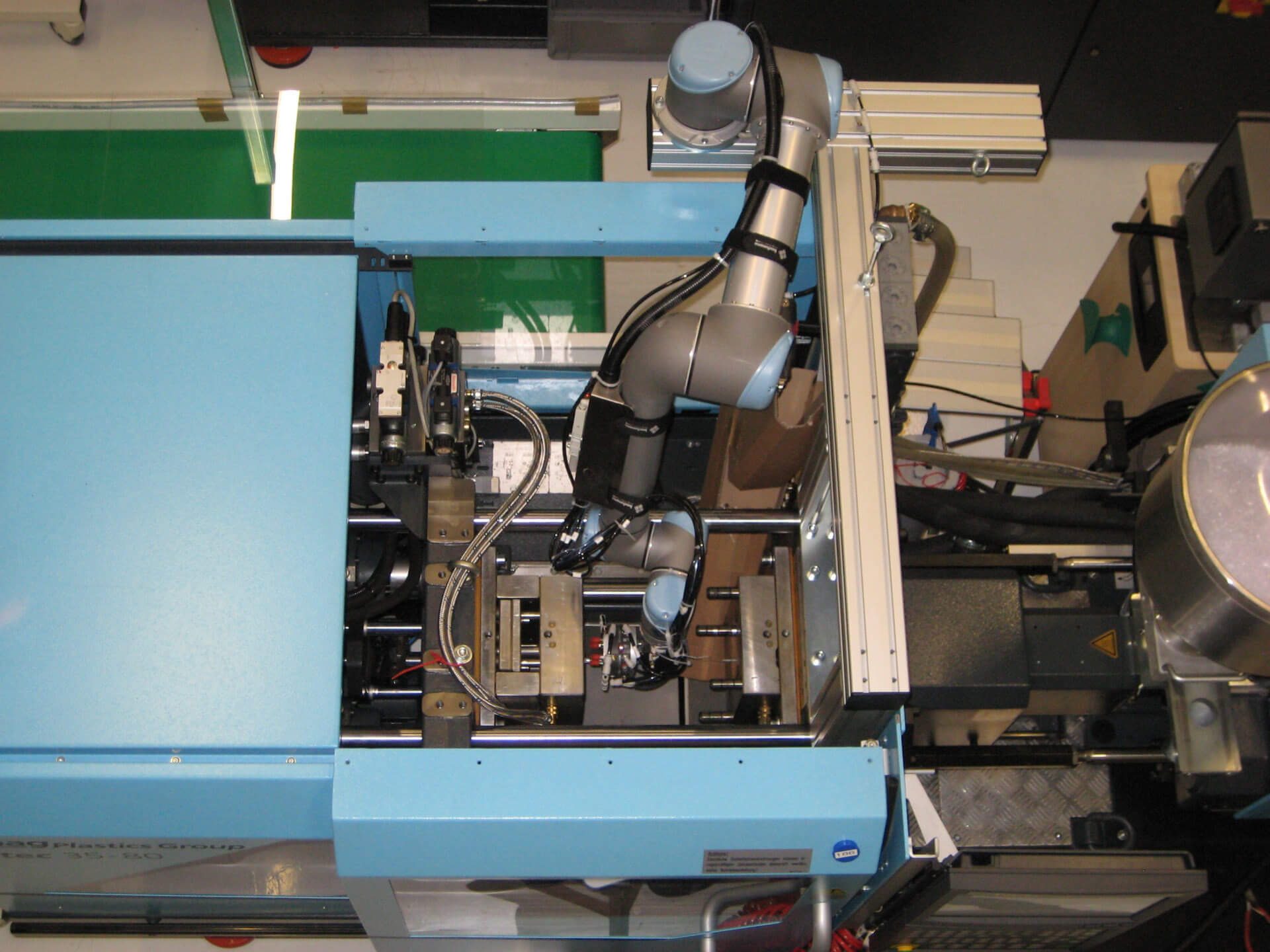

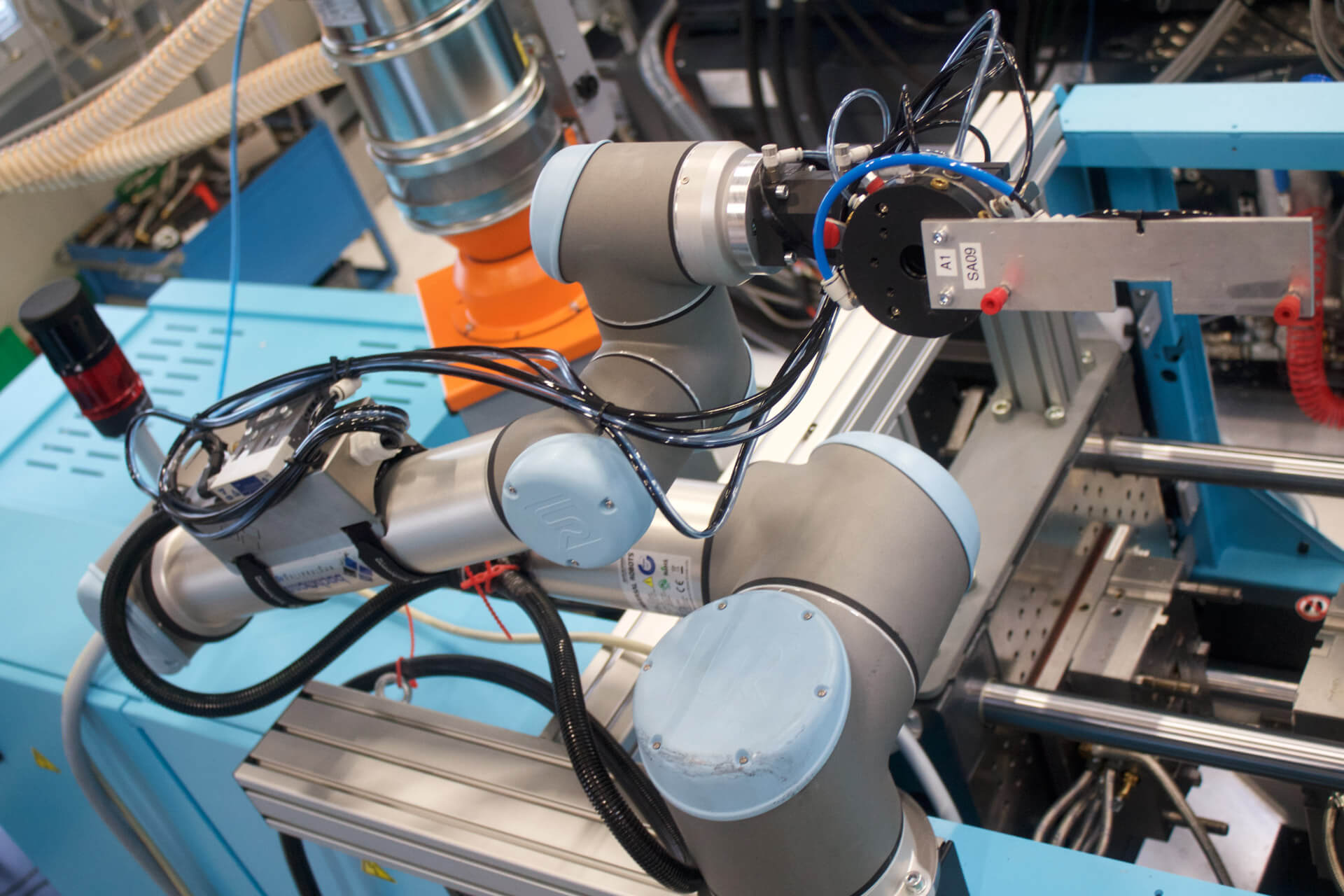

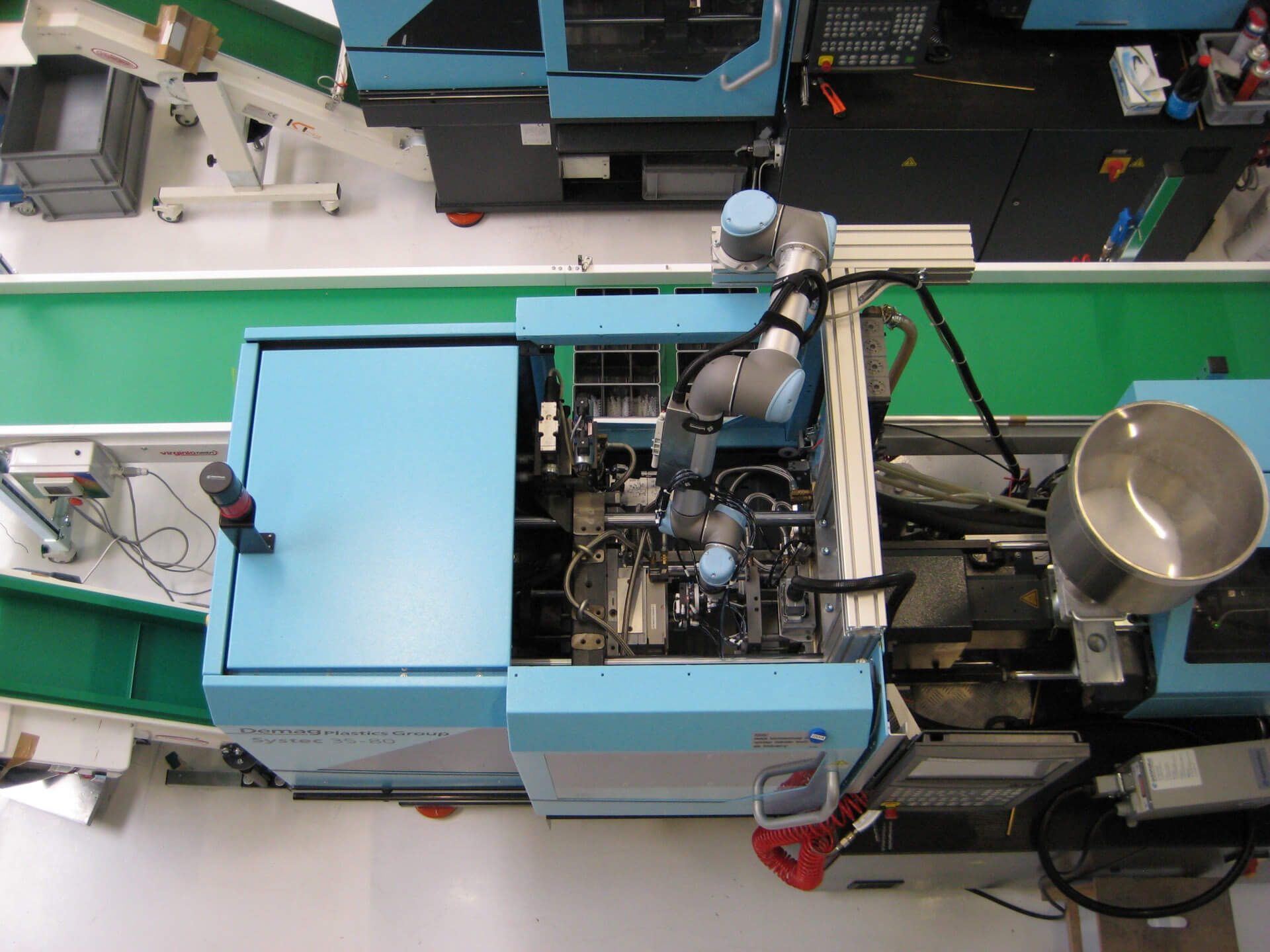

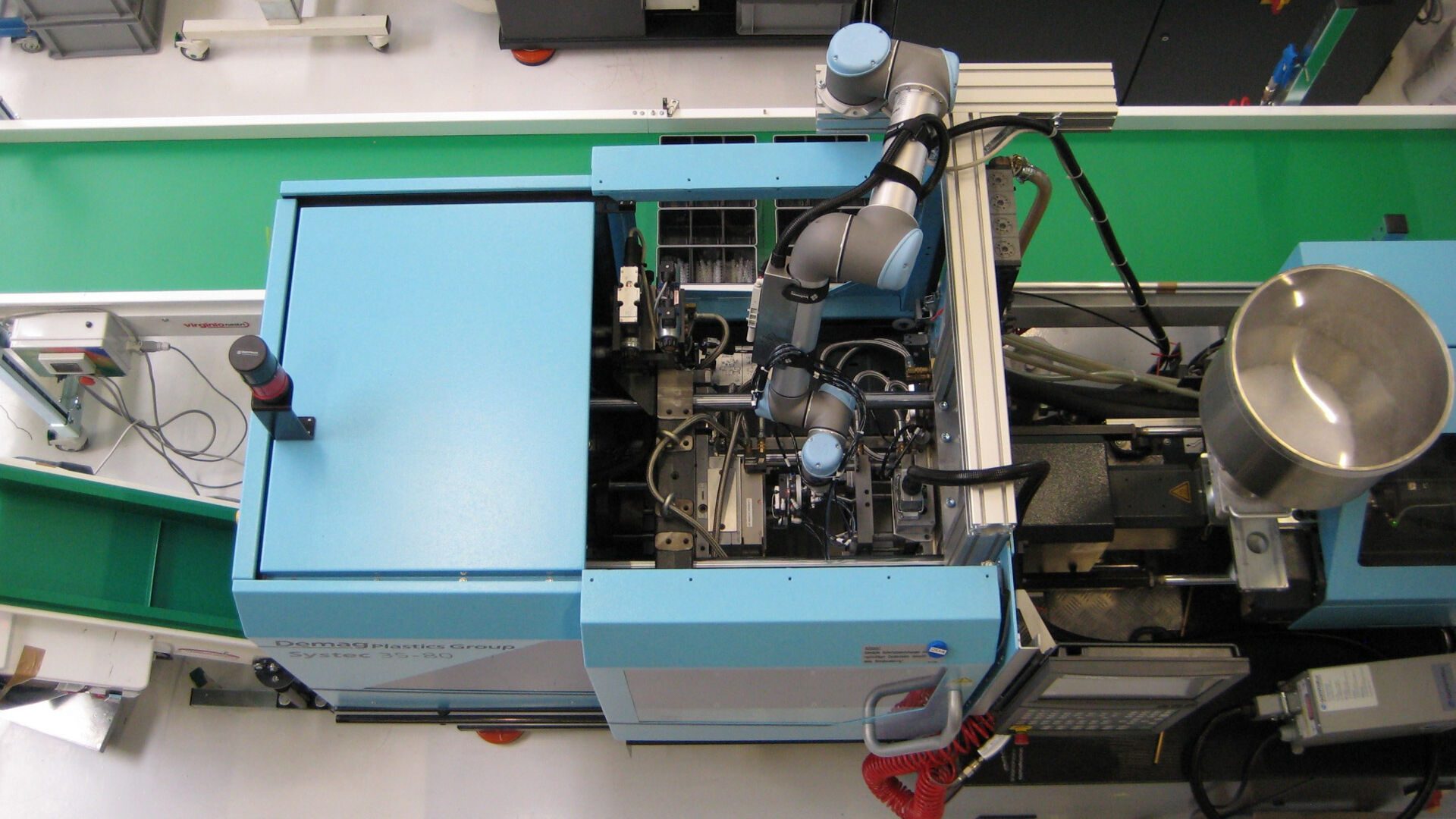

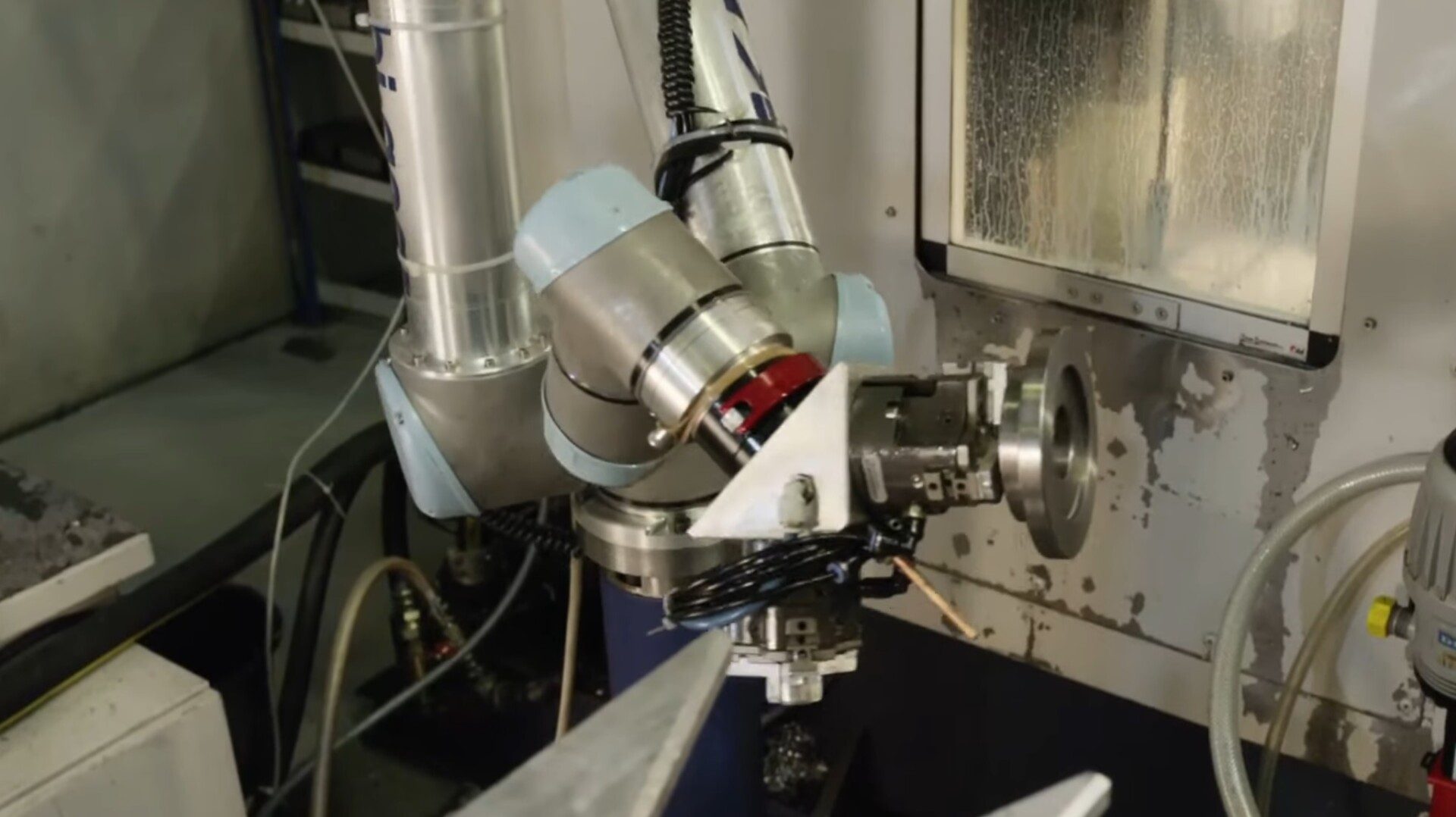

A UR5 robot was used for an initial test. The robot could be used flexibly on 5 injection molding machines and was completely convincing with the results.

Following the test phase, Profatec invested in two more collaborative robots from Universal Robots, namely two UR10s. This enables the company to expand production, reduce costs and increase profitability. Profatec can use the UR5 and UR10 robots on any machine. At 10 kg, the UR10 robots have a higher load capacity and a larger working radius of 1300 mm than the UR5.