What is a cobot?

In today's ever-evolving world of robotics, there are a growing number of innovative solutions that aim to improve collaboration between humans and machines. One of these solutions are cobots, collaborative robots that are becoming increasingly common in various industries. In this article, we would like to give you a comprehensive overview of what a cobot is, how it differs from conventional industrial robots, what applications there are for them and the benefits and concerns associated with their use.

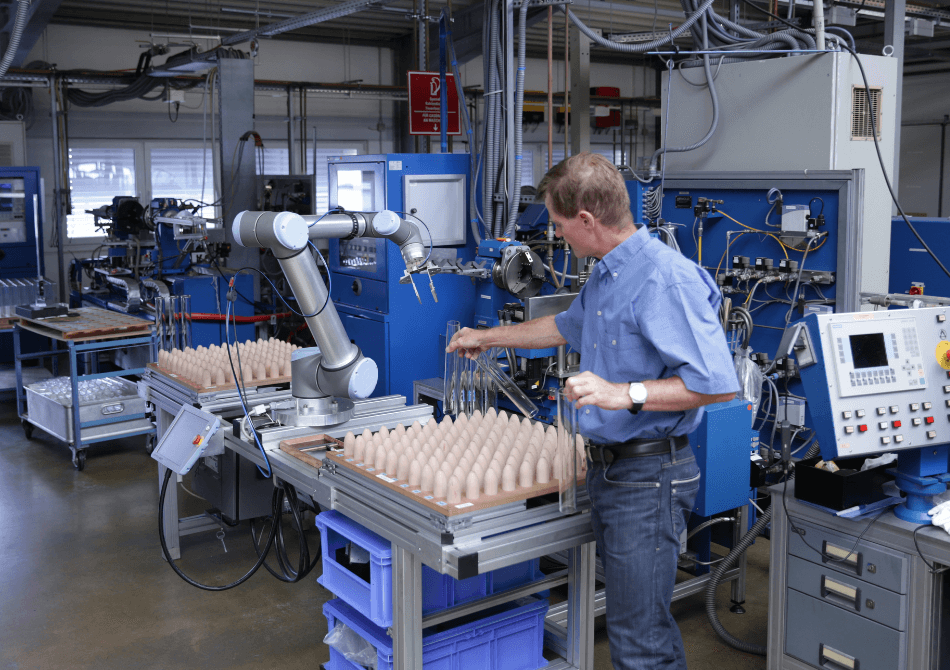

A cobot, or collaborative robot, is a type of robot that is designed to interact and collaborate hand-in-hand with humans in a shared work environment. They are equipped with advanced sensors and control systems that allow them to respond to the movements and actions of their human colleagues. Unlike traditional industrial robots, which typically work in segregated areas or behind safety fences, collaborative robots are designed to be used safely in close proximity to humans. This enables improved collaboration and efficiency in various work processes.

Application examples

A cobot can be used in a variety of industries to perform different tasks in collaboration with human workers. Here are some examples:

- Mechanical engineering: In the mechanical engineering industry, a cobot can be used for assembly, grinding, polishing or quality control. It allows employees to concentrate on more complex tasks while it takes over repetitive and tedious activities.

- Electronics industry: In the electronics industry, cobots can be used in the assembly of printed circuit boards, the soldering of components or the testing of electronic parts. Thanks to their precision and flexibility, they support employees in demanding tasks.

- Pharmaceutical and chemical industry: A cobot can be used in laboratories and production facilities to take samples, fill liquids or mix reagents, for example. It ensures greater safety and accuracy in these sensitive work areas. Read our free e-book about cobots in the chemical and pharmaceutical industry.

- Food industry: Collaborative robotics can be used in the processing, packaging or labeling of food. Thanks to its hygienic design and the ability to easily adapt to changing production requirements, the cobot can help to increase productivity and quality.

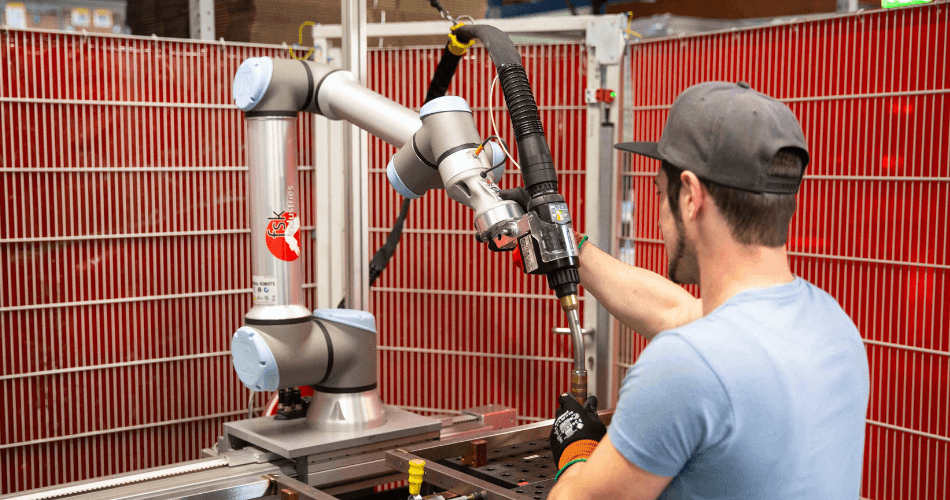

- Welding industry: A cobot can be used in the welding industry, for example to ensure precise and safe welding of metal parts, such as in watchmaking. It can take over the welding seam guidance and ensure consistent quality while the human worker focuses on other tasks.

These examples show that cobots are a valuable addition to human employees in various industries represented in Switzerland and help to increase productivity and quality of work.

Advantages of a cobot for companies and employees

Advantages of a cobot for companies and employees:

The use of a cobot offers a number of benefits for both companies and employees, helping to increase efficiency and job satisfaction. Some of the key benefits that a cobot brings are:

- Safety: Thanks to its safety sensors and the ability to work in close proximity to people, a cobot can reduce the risk of accidents at work and thus ensure a safer working environment.

- Flexibility: A cobot is easily adaptable and can be quickly converted for new tasks if required. This enables companies to make their production processes more flexible and react more quickly to market changes.

- Increased efficiency: Work processes can be optimized through collaboration between a cobot and human employees, resulting in higher productivity and efficiency. A cobot can take over repetitive or tedious tasks, allowing employees to focus on more complex and creative activities.

- Cost savings: The introduction of a cobot can lead to long-term cost savings, for example by reducing production times, lowering reject rates or optimizing personnel costs.

- Increased employee satisfaction: By relieving employees of monotonous and physically demanding tasks, a cobot can help to increase job satisfaction and motivation. In addition, the use of a cobot promotes the further training and qualification of employees, as they have to deal with new technologies and working methods.

- Quality assurance: A cobot can help to improve the quality of the products produced by reducing human error in tasks that require precision and accuracy.

These benefits show that the use of a cobot in companies can lead to a win-win situation for employers and employees by increasing productivity and improving the working environment at the same time.

What needs to be considered when buying a cobot?

Although there are many benefits to using a cobot, there are also some concerns that should be considered. Here are some of the most common concerns:

- Job loss: One of the biggest concerns associated with a cobot is the fear that it could replace human jobs. However, it is important to emphasize that a cobot is usually designed to work alongside humans and support them in their work, rather than replace them. The introduction of a cobot may even create new jobs by promoting the need for specialized skilled workers.

- Data privacy and security: As a cobot is networked with different technologies and systems, this can raise concerns about data privacy and security. Companies need to ensure that they take appropriate measures to protect data integrity and ensure the safety of their employees and operations.

- Investment costs: The purchase of a cobot can represent a significant investment for companies. It is important that companies weigh up the long-term benefits and cost savings that a cobot can bring against the initial investment costs.

- Adaptation and training: Introducing a cobot into the workflow can mean a change for employees. It is important that companies invest sufficient time and resources in training their employees to ensure that they are familiar with operating and working with a cobot.

- Maintenance and servicing: As with any machine, a cobot requires regular maintenance and servicing in order to function optimally. Companies need to be aware of the requirements associated with maintaining a cobot and allocate the appropriate resources.

Despite these concerns, many of the challenges mentioned can be overcome through careful planning, investment in staff training and development, and consideration of long-term benefits and cost savings. If these aspects are taken into account, the use of a cobot can be of great benefit to many companies and employees.

Summary of the most important points and outlook for the future of cobots

A cobot, or collaborative robot, is a type of robot designed to work directly with humans and assist them with various tasks. Unlike traditional industrial robots that work in segregated areas, cobots are safe and flexible enough to be used side-by-side with human workers.

Cobots are used in a wide range of industries worldwide, from mechanical engineering and electronics to the pharmaceutical, chemical and food industries. In Switzerland, for example, cobots can be found in the welding industry, where they play an important role in the precise production of metal parts.

The benefits of a cobot include improved safety, flexibility, increased efficiency, cost savings, increased employee satisfaction and quality assurance. Despite potential concerns such as job loss, data protection, security and investment costs, cobots offer a win-win situation for employers and employees if they are carefully implemented and integrated into the workflow.

The future of cobots looks promising as they continue to evolve to become even safer, more efficient and more versatile. They are expected to play an increasingly important role in the world of work, helping to boost productivity and innovation while improving working conditions for employees.

The growing use of cobots shows that they are an important tool for modern companies that want to maintain and increase their competitiveness. Through collaboration between humans and cobots, companies can respond to future challenges and pave the way for a more productive and satisfying working environment.