Companies are increasingly thinking about mobile cobot solutions. Especially with frequent product changes, small batch sizes and fast delivery times, cobots need to be flexible and effective. A mobile base makes this possible. However, the question remains as to which solutions are available and when such a solution is worthwhile.

You can find answers to these questions here.

Why are mobile cobots becoming increasingly popular?

Mobile cobots provide the answers to questions that arise every day in production:

- How can the machines be used even more efficiently?

- How can processes be automated flexibly and effectively?

- How can even the smallest companies be globally competitive?

Cobots are lightweight robots. This means that collaborative robots can be used for more than just static applications. A UR3e, for example, weighs just 11 kg. Flexible use is thus easily possible. The cobot can then be seen as a tool in the toolbox that is always used where it is needed. But that's not all. The footprint is also very small. Conventional industrial robots quickly reach their limits due to their space requirements. Cobots are completely different. They can work reliably even in confined spaces. This compactness makes cobots ideal for mobile robotics.

How can cobots be mobilized?

We present three ways in which you can make your Cobot mobile. These three solutions are: Our integrators to support you, solutions under the UR+ products and self-designed constructions.

Implementation with our integrators

Our network of integrators supports you as a user and develops the right application. Even if you want to make your cobot mobile.

UR+ for more mobility

The UR+ solutions also include a number of options for mobilizing your Cobot. We will gradually make these solutions available here in Switzerland too.

Your own implementation

There are companies that like to develop their own solution for the mobility of cobots. One example is Hofman Glastechnik GmbH. They have mobilized their cobots using their own design.

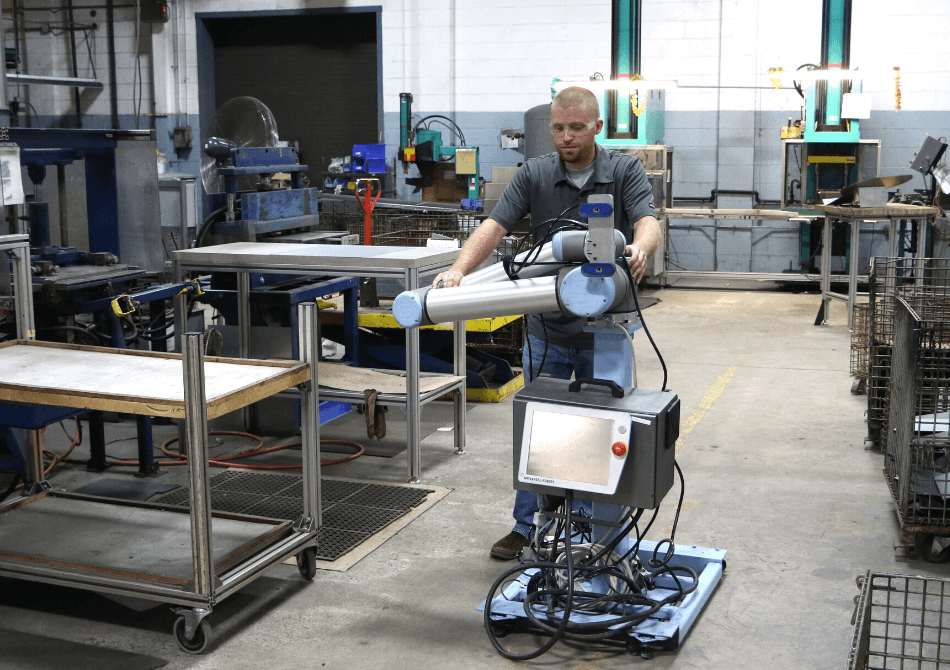

The fleet of mobile cobots is integrated into the entire production cycle at Scott Fetzer.

Optimizing production with mobile cobots

The company Scott Fetzer has been using mobile cobots in production since 2015. The cobots are mounted on bases with wheels. This mobility is necessary as the product mix is varied and the quantities are low. Depending on requirements, the cobots can therefore be used throughout the entire production process. Applications range from cutting on the cutting press to forming, folding and assembling electrical components. The mobile robots have enabled Scott Fetzer to optimize its production by 20 percent.

Mobile cobots help your skilled workers

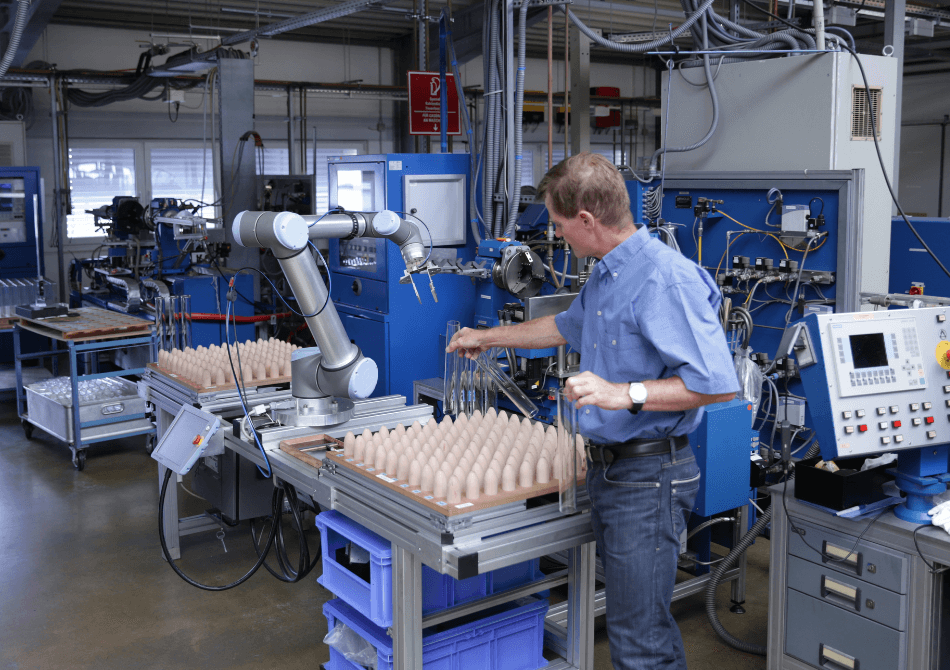

Hofmann Glastechnik GmbH also uses mobile cobots. With the 4 cobots, the skilled workers are to be better utilized and the processes further optimized.

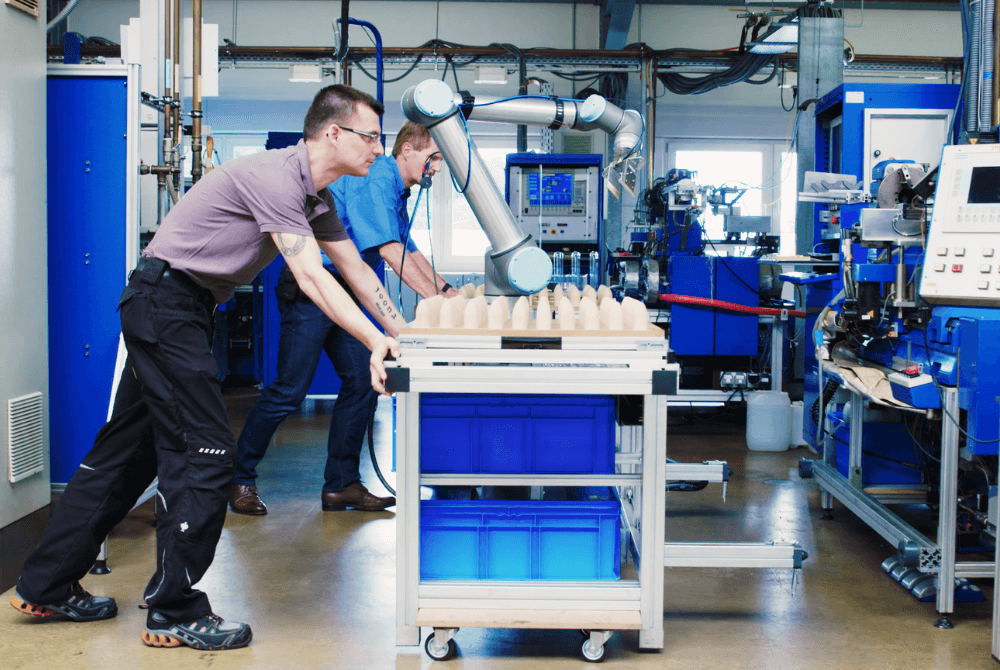

Two of the cobots feed several PLC-controlled glass lathes for up to 11 hours a day. Hofmann has developed its own mobile device that enables them to easily move the cobots between the machines. The employees are convinced by this solution, as it makes their work processes much easier.

The mobile cobots at Hofmann Glastechnik GmbH are attached to different machines as required.

Find mobile potential

When companies use mobile cobots, there are even more opportunities to fully exploit the potential of cobots. You should always ask yourself whether a mobile version makes more sense for your application. If the cobot is not fully utilized with one application, then you should definitely consider a mobile solution.