Welders are currently in high demand. However, there are hardly any qualified specialists left. Therefore, the available skilled workers must be deployed as effectively as possible in order to be able to handle all the orders. But that's not all. Cost pressure is also increasing in competitive markets. However, producing as cheaply as possible is not enough. Quality requirements are increasing to the same extent.

How can collaborative robots help in this situation? We will show you how you can make optimum use of your resources with cobots and meet the increasing demands.

Which cobot is suitable for welding?

Many companies in numerous industries are already using cobots to relieve employees of heavy and tiring routine work. In doing so, they are actively combating the shortage of skilled workers. Another side effect is the increased attractiveness. This new technology makes the company more attractive to young, tech-savvy specialists.

Which cobot is the right one? The UR10e is particularly suitable for the welding set. It has a space-saving design and can therefore be easily accommodated even in small workshops. Its load capacity of 12.5 kg is sufficient for most welding jobs. Its reach of 1.3 m even allows it to be used on larger welding benches.

Added to this is the repeat accuracy of +/- 0.05 mm, which is important for top quality weld seams. Time-consuming reworking is therefore not necessary with welding cobots. The welding scobot even reduces rejects.

What is the right layout for cobot welding?

There are various ways in which companies can integrate the UR10e into existing processes:

- If you want to get started quickly and easily, the Cobot can simply be placed on an existing welding workbench.

- A welding scobot positioned between two stations is optimally utilized. It can weld at one table while an employee prepares parts at the other table.

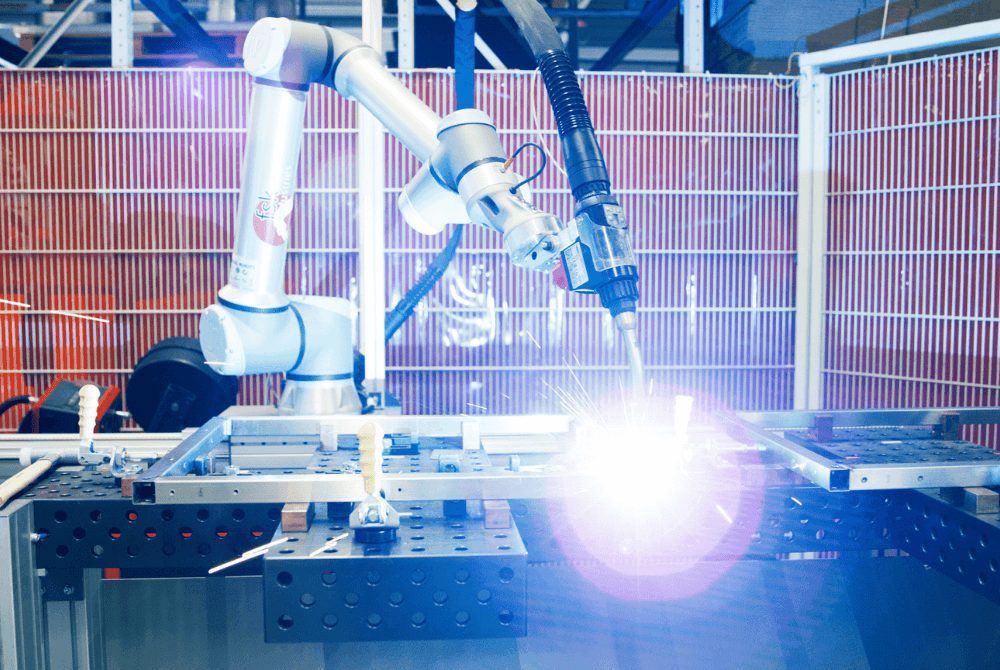

- There is the option of highly automated welding cells. These cells are then closed and have two stations with an integrated linear axis. This design is similar to traditional welding cells. However, the programming interface of the cobots is much more intuitive than that of industrial robots. Therefore, anyone can operate it.

We recommend the help of an expert, such as Arnold Schweisstechnik from Seedorf.

An expert can implement the best solution for you and make smooth integration possible.

How do companies use welding cobots?

Köhler MFE GmbH also uses a cobot for welding. The Cobot welds stainless steel parts, which are then used to produce work furniture for the food industry.

The Cobot welding system consists of two stations that are connected by a linear axis. The employees insert new parts on one side of the cell, while a UR10e welds the assembly together in the other area. Thanks to the linear axis, the cobot can flexibly switch back and forth between the areas.

By using the cobot, Köhler was able to halve the duration of the welding process. In addition, the Cobot's weld seams are extremely uniform. Even when the cobot is welding around the clock.

Small and medium-sized companies in particular benefit from welding with cobots.