Many companies had to reorganize during the coronavirus pandemic. Production had to be reorganized at short notice. Companies that previously produced spirits, for example, now produced disinfectants. This showed that companies that can react flexibly have an advantage. While the economy stumbled, orders fell sharply and production came to a standstill, something very good happened. Medium-sized companies were looking around for new ideas. The use of collaborative robots is one of these ideas.

Entrepreneurs focus on innovation

Manufacturers are increasingly prepared to respond to economic problems with innovations. A large proportion of companies have made adjustments to their service and product portfolio or to their structures. Many companies are still planning adjustments.

One of these adjustments is the automation of production. With this adaptation, companies are significantly more resilient in crises. Cobots help companies to improve their adaptability and react more quickly to market changes.

Many specialists and managers expect an automation boom in the coming years. It was already known that automation was important. But the crisis has brought a new urgency.

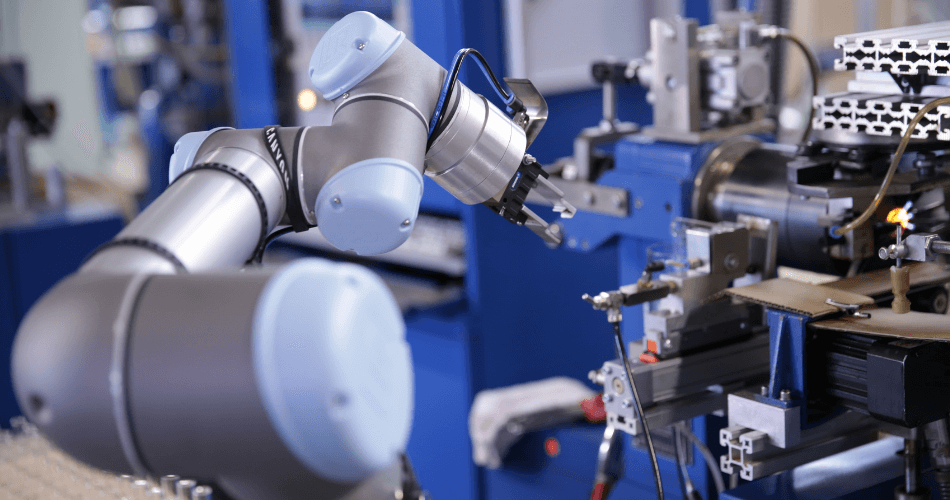

Hofman Glastechnik also relies on automated production processes to increase the quality of its products for the medical industry.

Supply chains cannot always be relied on

Reshoring is a term that was used more and more frequently during the coronavirus crisis. Long-established networks began to falter and it quickly became clear that replacements were needed for many supply chains. This replacement must also be effective in the event of market changes and delivery difficulties. It also became clear that proximity to the customer was more important than lower labor costs abroad.

In this trade-off between higher labor costs and lower dependencies, collaborative robots show their strengths. With cobots, companies can quickly reap the benefits of automation. Why is that? Cobots are particularly easy to operate. No specially trained personnel are required, as programming is very simple. Employees can set up and operate the cobot after just a few hours.

In addition, there is no need for the expensive protective housing that is otherwise required for industrial robots. This gives small and medium-sized companies the opportunity to produce domestically themselves. This reduces their dependence on international supply chains. Despite manufacturing in a high-wage country, companies that use cobots can sell at competitive prices.

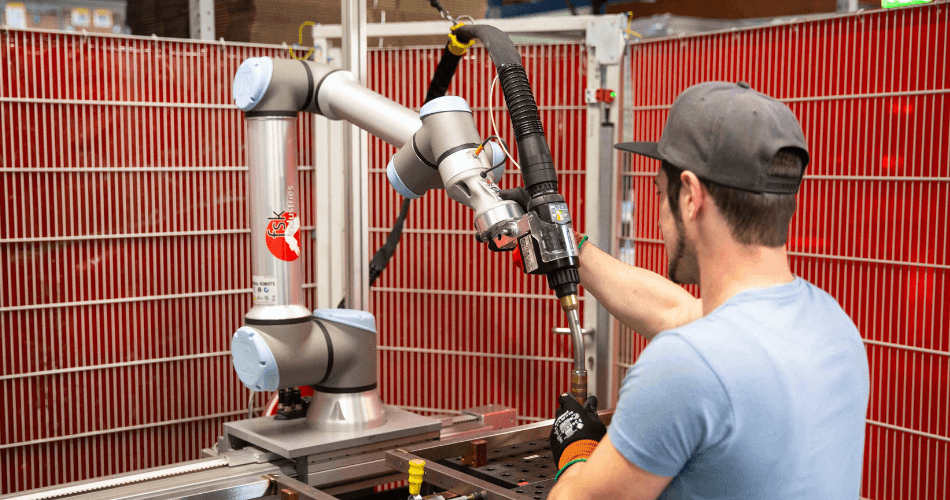

The food industry is booming. That's why mobile food equipment manufacturer Köhler has a lot to do. The Schweisscobot is doing a good job and helping to meet demand.

Skilled workers must be better deployed

Working from home, absence due to childcare, illness. All of these things happened frequently last year. Even manufacturing companies had to weigh up various risks. The risk of quarantining all employees is high if everyone is working at the same time.

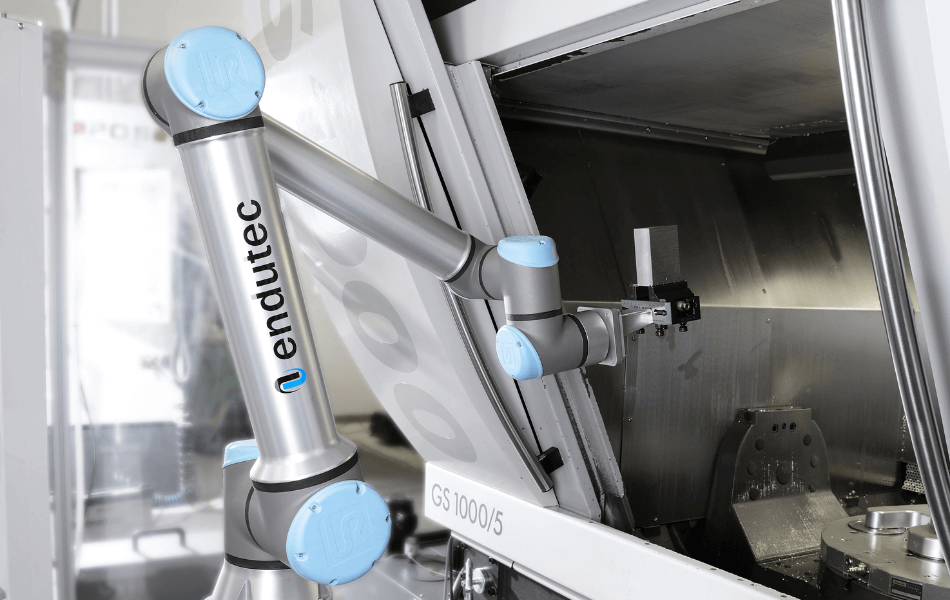

Companies that had already automated parts of their production with cobots had a clear advantage in this situation. One example is the special machine manufacturer Endutec. Since 2018, the company has been using a UR10e to load a CNC machine during the night shift. The company was therefore able to send some of its employees to the home office without any loss of production. They were able to write new CNC programs there.

During this crisis, the needs of employees became more and more prominent. Since then, there has been an increased focus on the health and individual workload of employees. Many skilled workers are still performing unergonomic, sometimes even dangerous and monotonous tasks in production. This ties up valuable skilled workers in tasks that cobots can also perform. If you use a cobot for these tasks, you relieve your employees, who can now make much better use of their valuable skills.

The UR10e feeds a machine so that corona-compliant production can take place.

Necessity is the mother of invention

In times of crisis, companies are increasingly looking for innovations and new ways to make even better use of existing resources. The automation of production with cobots is one of these innovations. Even industries in which cobots have previously played a minor role are showing an interest in cobots and are using collaborative robots for more and more applications.

Cobots have been used as disinfection robots in airports, train stations, care homes and hospitals, for example. Even throat swabs are performed by cobots.

This shows us that there is still a lot of potential for automation with cobots. No matter what industry, no matter what application, cobots can play a role.