The chemical and pharmaceutical industries are among the fastest-growing and most innovative industries in Switzerland. This has been possible to date despite rising cost pressure, increasing competition and the continuing shortage of skilled workers. In order to continue to produce competitively and innovatively in Switzerland in the future, the entire industry needs to rethink its approach.

For example, the automation of production processes with collaborative robots is contributing to continued success.

In this article, we show you how international companies are using collaborative robots (cobots) in their production to relieve and support employees

What work can be automated with cobots in the chemical and pharmaceutical industries?

The collaborative robots are suitable for the automation of many different tasks. They can be used to easily automate inspection, mixing, dosing, filling and packaging. The cobots support your employees, relieve them of tedious and repetitive tasks and ensure a significant increase in efficiency. They help with laboratory analyses, tests, injection molding tasks and pick and place applications. Collaborative robots can also be used to operate machines.

Your employees are relieved by these robot arms. A robot arm is not bothered by tasks that are hazardous to health, dirty or strenuous. At the same time, they carry out their work extremely accurately and quickly. This means that the strictest quality standards can be maintained without compromising competitiveness.

Collaborative robots in the lab

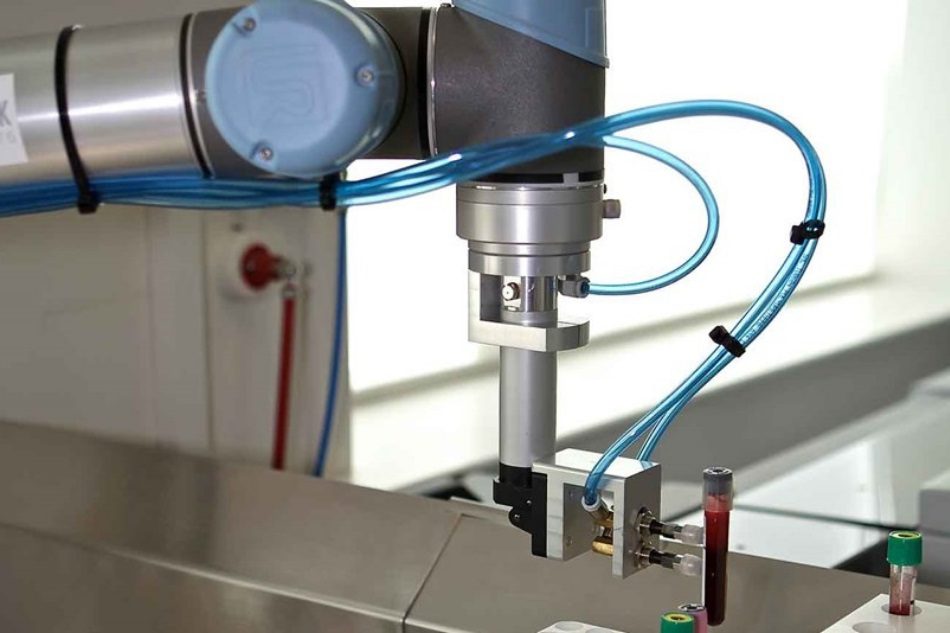

Cobots are being used at Copenhagen University Hospital to improve patient care. The cobots are not used in care, but in the hospital's laboratory. In the laboratory, the UR5 robots from Universal Robots relieve the laboratory staff of time-consuming and monotonous tasks. They sort 7-8 samples per minute and 3,000 tubes per day. A camera system helps with this. The robots then sort the samples into the appropriate compartment according to color. The robots then remove the tubes and place them in a device for centrifugation and analysis.

"Our staff welcomed these robots enthusiastically. They know that every blood sample not analyzed in the lab means a patient waiting. Delivering almost all blood test results within an hour means that our outpatients save a trip to the hospital as their hospital doctor now gets the results back during the same visit. Results for samples taken in the morning from inpatients are available before the morning visit."

Collaborative robots in logistics

RNB Cosmeticos is a cosmetics company that also uses collaborative robots. Here, six UR10 robot arms are used in the cosmetics laboratory. They take over the heavy task of palletizing and thus significantly relieve the employees. They can now take care of other much more important tasks. The cobots stack the heavy packages with ease.

"We don't hire experts to operate a high-tech robot. We turn our employees into experts whose level of qualification is constantly increasing."

At MARKA, an Italian chemical company, a UR3 Cobot helps to maintain performance and quality levels. This means that cleaning agents can be produced despite smaller batches. The robot arm continuously and precisely places caps on bottles and then tightens them.

"Thanks to the robot from Universal Robots, we were able to increase the overall quality of the finished product and recover the acquisition costs within a year."

In order to continue to operate successfully, companies in the chemical and pharmaceutical industries should implement efficient solutions to counter the growing cost pressure. Cobots can be easily and flexibly integrated into many production lines.